# Maintain Leadership in the domestic market and establish leadership in new market.

# Ensure customer satisfaction through timely delivery of product and service at competitive rates and continual improvement.

# Continue improvement in process technology and work environment to offer better value addition

BBW EDGE

a) HEAT TREATMENT :

Uniform heat treatments in clips are achieved with BBW’s special Heat Treatment Process. BBW also follows Customer Specific Heat Treatment Processes viz., Aus-Tempering, SQF Processes

b) SURFACE COATING :

BBW does various Surface Coatings as per Customer Requirement.

ZINC ELECTRO PLATING: Plating is done in an Automatic Plant and all the clips are subjected to Hydrogen De-Embrittlement.

MAGNI /ATOTECH / DORKEN / GEOMET COATING: These are high performance, chrome-free zinc flake thin film coatings given on the product. SST requirement of 480 to 2000 hours can be met with these processes.

CED + Top Paint: As per customer requirement CED is done as base coating and Top Painting is done. This process withstands minimum 800 hours Salt Spray.

SILVER SYNTHETIC COATING: This is a popular Coating in Wheel Balance Weights. This process withstands minimum 800 hours Salt Spray.

c) CASTING:

BBW has fully automatic casting facility. Very stringent grammage and clip-gap tolerance is ensured which results in excellent process capabilities.

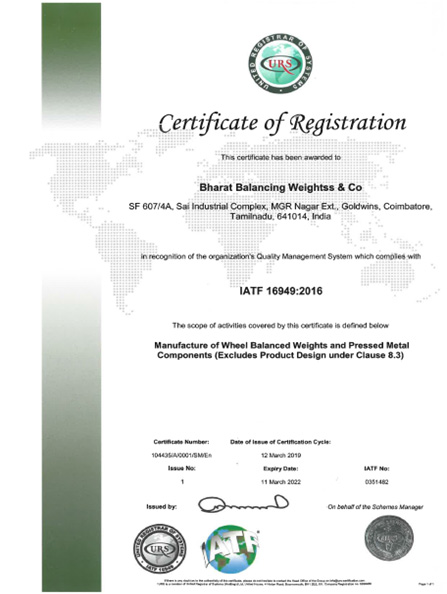

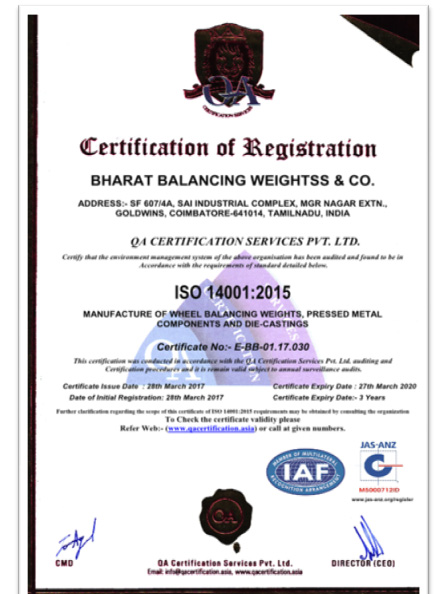

QUALITY CERTIFICATE

BBW is certified with IATF 16949:2016 and ISO 14001:2015.

INSPECTION TESTING

BBW is equipped with full fledged inspection and testing facility.

Following key parameters are inspected periodically

- Lateral Load

- Sliding Load

- Shearing Load

- Clip-Gap

- Weight Grammage

- Weight Separation

- Drum test